Techinomics Rotating Throat Features

- Increase coal throughput

- Improve coal stream fineness

- Improve Primary Classification

- Lower NOx in your pulverizer - increase Lo-NOx burner efficiency

- Extend SCR catalyst life

- Reduce boiler slagging

- Extend periods between Overhauls

- Reduce pre-combustion mercury

- Installs in as little as 3 shifts

Independent side by side testing at a

Southeastern US coal plant demonstrates

Techinomics' unmatched ability to remove

Mercury-Arsenic-Lead-Antimony

PRE-COMBUSTION

See Report Here

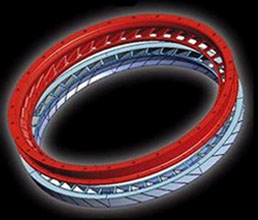

The Techinomics Rotating Throat-Ledge Cover System features patented ledge cover and inlet vane design that provides unique and unmatched performance in several key areas. The throat design incorporates a venturi effect and converging-diverging nozzle which converts pressure to velocity, returning more over-sized coal particles back to the working zone for additional re-grinding without blowing the pyretic rock back or clogging the ports. The Techinomics design allows for a superior primary classification process. The pyretic rock, which even in pre-washed bituminous coal contains significant concentrations of Mercury is removed from the coal stream at an un-matched rate. The vane design coupled with the throats high-pressure drop system allows us to increase velocity without increasing primary air flow mass.

- Less primary air mass in the pulverizer means less oxygen available to form NOx.

- Less NOx in the system means more efficient Low NOx burner operation and extended life for your SCR catalyst.

- Because we produce a finer, more combustion efficient coal stream, with significantly reduced pyretic rock content, there is less rock available to cause boiler back pass erosion. Less maintenance cost- longer intervals between overhauls.

Techinomics Installation

Techinomics throats with wear resistant roll wheel and grinding table

Designed for Efficiency